Now we have to make sure the cartridge’s vertical tracking force (VTF) is the correct one as suggested by the manufacturer. In order to do this, we have to lower the cueing bar and keep the tonearm between our fingers (out of the record’s surface!) while moving the counterweight back and forth (the TP-11’s in the picture below must be rotated clockwise and counterclockwise) until the tonearm, headshell and cartridge in place, is perfectly horizontal, balanced between the cartridge’s mass and the counterweight. With the TP-11, at this point you can move the VTF indicator to zero and rotate the counterweight to the desired value. It is strongly advisable to purchase a digital or analogue VTF meter so that you can check the value with a much higher precision.

The antiskating bias is a mechanism meant to counterbalance the centripetal force that drags the tonearm towards the record’s center during the reading. The groove’s inner wall (the one towards the center of the record) contain the left channel modulation, therefore this should result more “highlighted” if there was no or too little antiskating force (generally, you should notice a duller right channel and some distortion of the higher frequencies, especially on the sibilants in the same channel). With time, this could bring to an earlier wear of one groove’s wall and of the stylus tip. By applying a proper counter-force (centrifugal), even the external groove’s wall, the right channel, will be correctly highlighted. With a properly balanced pressure on both the groove’s walls, the stylus tip will wear more slowly and the groove will almost not wear at all, provided it is well cleaned.

Actually, adjusting the antiskating to a value equal to VTF may result in an error, as well as adjusting it using a test record. The value of the center drag force that the cartridge undergoes in the groove also depends on how much it is modulated: in complex loud passages the groove is more modulated and the friction is greater; the opposite happens during the piano sections of a track. The ideal would be a dynamic variation in antiskating depending on the modulation of the passages. The tonearm designer Frank Schroeder has calculated that most modern music is at 80-90% of the time around 30-40% modulation. The test discs use very high level tracks to adjust the antiskating. The result is that we will have a stylus that pushes harder on the right groove (right channel) due to exaggerated antiskating for most of the time. In fact some cartridge repairers report that the vast majority of diamond tips are worn on the right side.

The solution? Adjust the antiskating by placing the stylus on the end of the record, towards the center just before it enters the exit groove. The unrecorded space between the tracks on some test records is also perfect. In those places the stylus should move slowly towards the centre of the disc, much slower than when dragged along in the groove. This will ensure the best antiskating value for any cartridge at any amount of VTF (the higher the VTF, the higher the friction on the vinyl, the higher the amount of antiskating to get the same result).

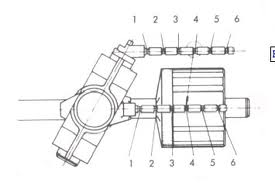

The TP-11 tonearm installed on Thorens TD-165/166 models has a little weight at the end of a thin nylon thread; it hangs from two horizontal rods with 6 grooves each (picture above): The nylon thread must be positioned on different grooves depending on the VTF in use. For example, in the common case of VTF=1.5 g, the Thorens manual suggests the number 1 grooves (the minimum antiskating value).

The Thorens TD-160’s TP-16 tonearm allows for a dynamical VTF setting. Once the tonearm is set to zero VTF by moving the counterweight back and forth until the arm is horizontal, you can move the indicator to the desired value: a spring system will load the cartridge correctly. When playing a warped disc, the systems varies the VTF dynamically while the cartridges follows the ups and downs of the record. In the back of the tonearm there is an additional knob for fine tuning with a VTF meter or gauge.

TP16 tonearm (MK1, more recent make) antiskating bias setting: upper scale is for wet surface (cleaning fluids are no longer used, therefore do not read on the upper scale). The lower scale is for dry surface, so it is the one to use; top readings are for spherical stylus tips, bottom readings are for elliptical tips. Here the bias is set to almost 1 for an elliptical stylus.

The TP-16’s antiskating system is based on a magnetic mechanisms: one magnet is fixed and the other one’s position can be adjusted by rotating the relevant knob (picture above); this provides the desired counterforce to the centripetal force the tonearm is subject to. The readings scale is rather cryptic, though…

TP16 tonearm (MK1, older make) antiskating bias setting: upper scale is for wet surface (cleaning fluids are no longer used, therefore do not read on the upper scale). The lower scale is for a dry surface, so it is the one to use; top readings are for spherical stylus tips, bottom readings are for elliptical tips. Here the bias is set to nearly 1.25 for an elliptical stylus.

Some believe that antiskating is not necessary if the vertical pressure (VTF) exerted by the head is slightly increased. I think it is better to apply a centrifugal force to the tonearm to balance the centripetal drag on the cartridge. In the past I have used a test disc to check the correct antiskating setting on both the Thorens TD-165 and TD-160. Some tracks on the record provide some tones that need to be played without distortion on both channels; as explained above, it is best to avoid adjusting the antiskating in this way because it would certainly get too high a value. Among the test tracks in question there is also a very long blank (unrecorded) space, more or less in the middle of the disc. This is very useful to verify the effectiveness of the antiskating force applied. On both turntables, by dropping the stylus in the middle of the space between two tracks it slid quite quickly towards the centre – further confirmation of the too low antiskating force. On the TP-11 on the Thorens TD-165 I had to move the weight wire over the second grooves of the arms to get the stylus to move slowly towards the centre of the record. On the Thorens TD-160 I also had to turn the knob back and forth, by trial and error, to get the right balance.