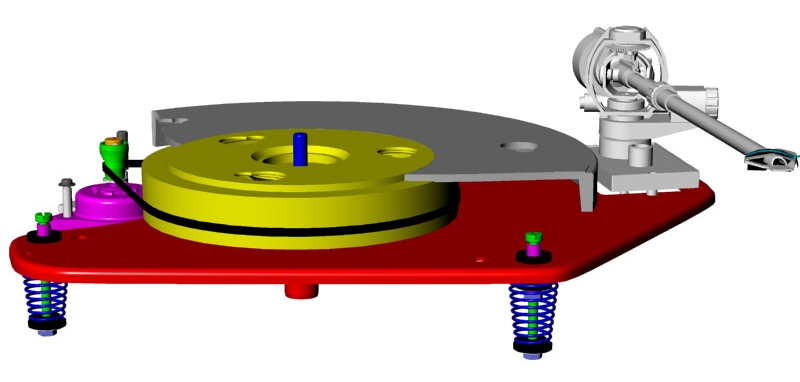

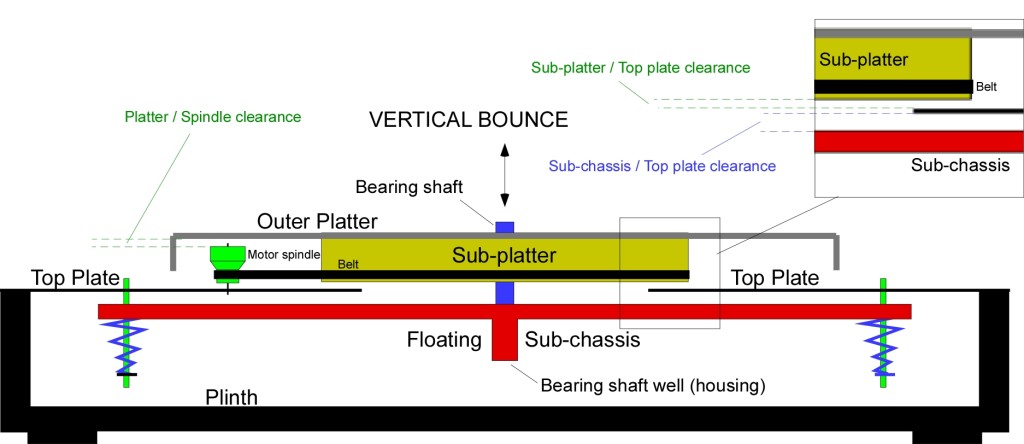

In a suspended turntable, the sub-chassis that carries the rotating platter and sub-platter is mechanically isolated from the motor plate (or top plate) by means of three adjustable springs. The goal is achieving a perfectly horizontal rotation and perfectly vertical bounce of the sub-platter/platter system.

Cut-out sketch of a Thorens TD-160 suspension assembly: the sub-platter (yellow) and the outer platter (gray) are both carried by the sub-chassis (red); the sub-chassis is connected to the motor board (not visible) by means of three suspension springs (blue) and relevant rods (green); adjusting nuts at the lower tip of the springs allow charging the three springs so that they perfectly level the rotating system along the horizontal plane (Picture from theanalogdept.com).

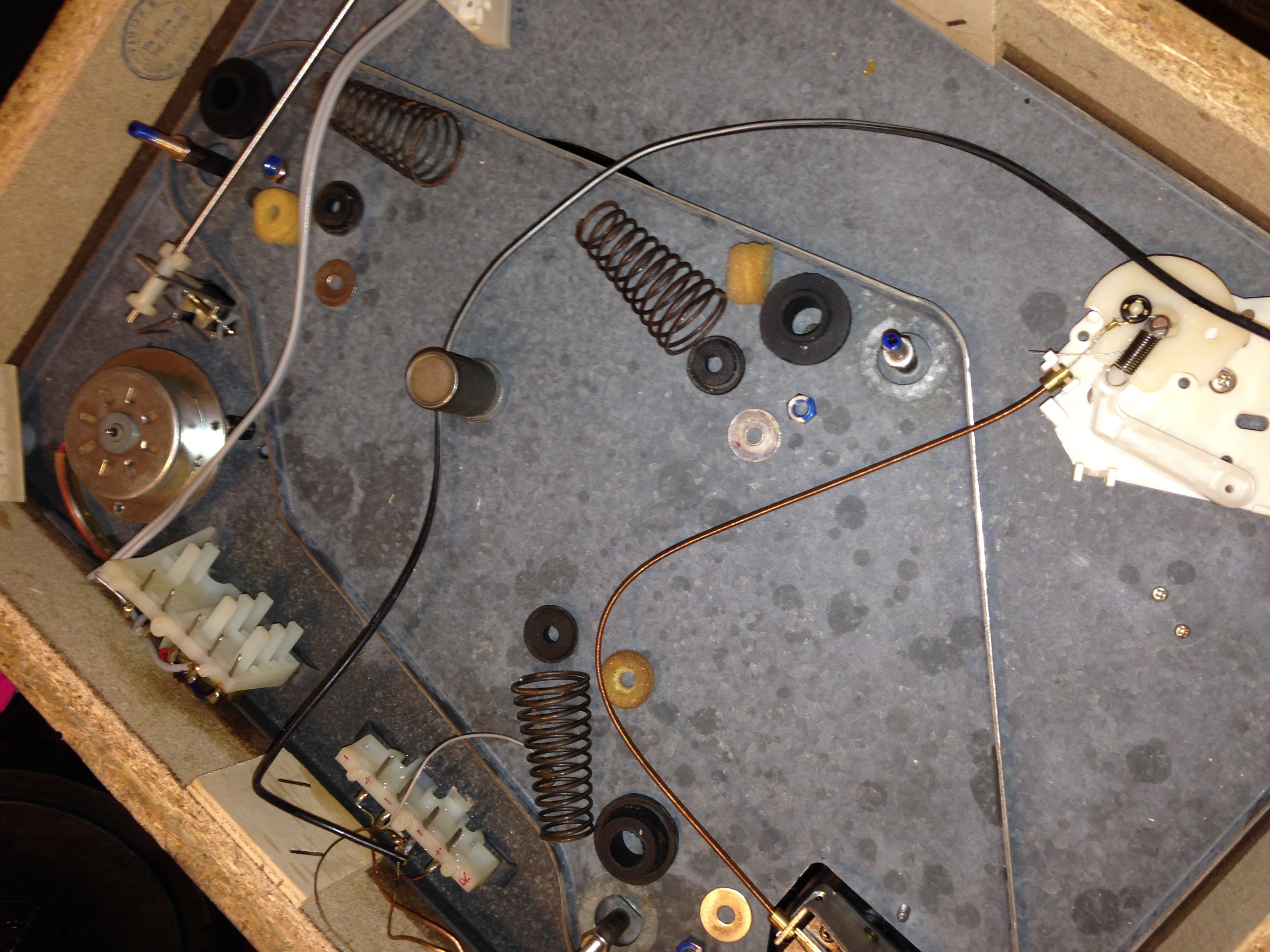

Thorens springs aged very well from the 70s. It is not likely they will need to be replaced. However, it is absolutely certain that an untouched Thorens table will desperately need a suspensions adjustment in order to provide the required leveling and isolation from motor and ambient vibrations.

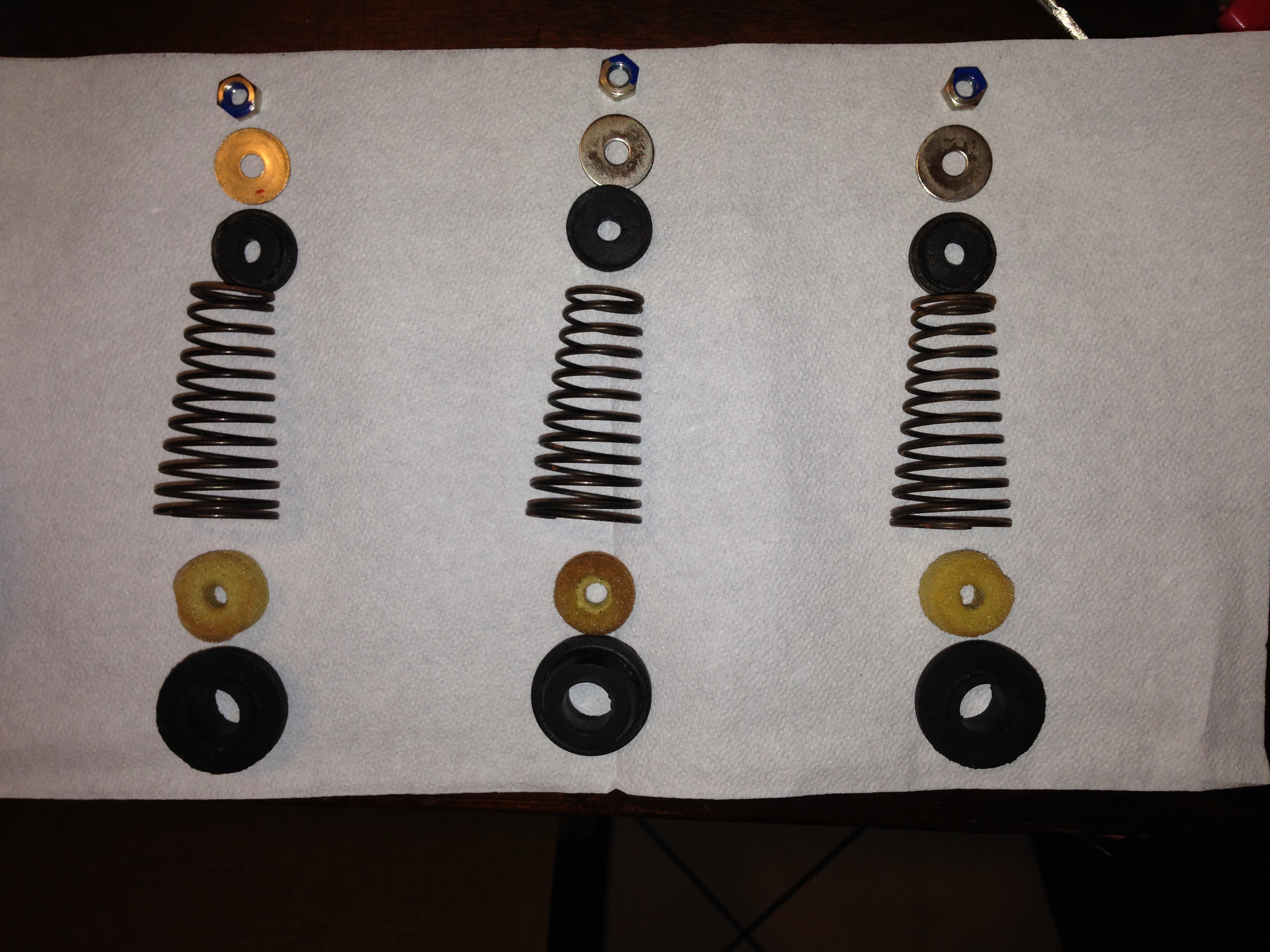

The suspension system is disassembled completely and thoroughly cleaned. It consists of three metal springs with top and bottom grommets. The bottom grommets are smaller and provide contact with the adjusting nuts and washers; the bigger, top grommets provide soft contact and centering to three holes in the sub-chassis. Originally there are three foam inserts probably meant to provide further isolation. It is debated whether they are functional or not. Many prefer to eliminate them. So do I.

The cleaning process

Adjusting the suspension of a Thorens turntable may be a demanding task.

It is a matter of patience and experience, and also a trial and error process. It may have to be repeated several times, often restarting from scratch, before achieving the desired results. While adjusting, the turntable must be in normal working conditions: platter, mat and a record must be on; the cartridge must be mounted and its vertical force set; an original dedicated Thorens-branded replacement belt must also mounted.

The sub-platter/sub-chassis system must float at a particular height so that the sub-chassis won’t touch the top plate above and the sub-platter won’t touch the top plate below, preventing rotation:

The “floating sub-chassis” design

Other than obtaining the required clearance between top plate and subplatter/subchassis, the suspension adjustment also affects the position of the belt, which shouldn’t slip out below the subplatter when it’s rotating at 33 RPM (like in the drawing above) or from the top of the motor pulley’s larger section when it’s rotating at 45 RPM.

The very delicate motor pulley could be hit by the heavy metal platter if the suspensions are adjusted too low – a damaged (bent) motor pulley would mean the whole motor should be replaced.

The springs must be dead centered around each rod in order to provide a perfectly vertical push on the subchassis, or the horizontal leveling won’t ever be achieved. When the springs are centered, the tonearm base is also centered in its rectangular cutout. The tonearm is fixed to the subchassis and bounces vertically along.

A correct suspension adjustment must provide an acceptable bounce: when gently tapping with a finger on the subplatter’s center shaft, the system should bounce 5-6 times, decreasing progressively in amplitude before stopping within 5-7 seconds .