Phono cables in the 70s where probably of lesser quality than today’s cables. Yet, one might want to preserve the vintage cables. If they are still working well, I have nothing against it: they were designed with the correct capacitance value for the tonearm wirings. Phono cables must meet certain requirements, especially regarding the low capacitance, which is affected by length and impedance.

If on good working order, the stock RCA plugs can be kept as they are, after a thorough cleaning with de-oxy. Often it is better to replaced them with modern gold-plated ones anyway.

Replacing the stock phono cables is something to be done with extreme care.

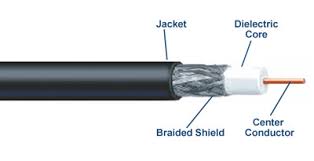

Phono signal cables should better be coaxial shielded cables (at right) of good quality. Low capacitance cables are often used for video applications, since they are standardly designed for a 75 ohm impedance which implies a low capacitance. Shielding is also very important for video applications, as it is for phono cables, since it isolates them form external interference. Microphone cables also have similar properties. I keep the length of each cable under 1 meter since the longer the cable, the higher its capacitance.

Regular coaxial cables do the job very well. I solder or quick-connect them to the terminal within the plinth. Notice that if modern cables are thicker than the originals it is not possible to keep the plastic boxes that isolate the phono terminals in the plinth. This may cause some additional hum, which can be resolved by ground rewiring (see below). If needed, a modern mains cable can be fitted in the isolation box, but those boxes are often missing in these Thorens turntables.

The best video cable available from the industry is the Belden 1505F video cable, the right mixture of size, flexibility and low capacitance. It also has a double braided shield. It is flexible enough for regular HiFi use, but for soldering inside a vintage Thorens cable it is a bit uncomfortable. After having tried thicker cables I decided to go for cables whose thickness is comparable to the stock ones: they can be fitted inside the cover boxes and are far more comfortable when transporting or moving the turntable. Provided they are good quality, the sound is not an issue.

The best video cable available from the industry is the Belden 1505F video cable, the right mixture of size, flexibility and low capacitance. It also has a double braided shield. It is flexible enough for regular HiFi use, but for soldering inside a vintage Thorens cable it is a bit uncomfortable. After having tried thicker cables I decided to go for cables whose thickness is comparable to the stock ones: they can be fitted inside the cover boxes and are far more comfortable when transporting or moving the turntable. Provided they are good quality, the sound is not an issue.

I can build the cables myself, but a good option is to purchase phono RCA interconnects designed for turntable use featuring:

- Neutrik gold plated RCA phono plugs, very tough and reliable

- 1.2 m Van Damme double shielded cable for ultra low noise and high RF rejection operation (80/0.10mm close lap copper screen and additional carbon thermoplastic inner screen)

- Ultra Pure Silver Plated Oxygen Free Copper (UPSPOFC) cable with thick 1.5mm PVC/Neoprene insulation and very low capacitance (certified for sub-zero use)

- Plug solder points insulated after soldering giving the cable extra reliability and full protection from cable fray shorts

- Cables fully tested after construction using a computer controlled dedicated cable tester that can detect shorts and resistive shorts with an accuracy of 1mS

- Tough 16AWG ground cable with insulated crimped M5 spade earth

Ground rewiring

Some Thorens turntables come with no grounding wire attached. Nonetheless, they have a thin cable connecting the right channel negative terminal to a screw in the sub-chassis. Following Thorens maintenance manual, I remove that connection from the terminal and connect the sub-chassis screw to another one I put in a pre-existing hole under the top plate, near the motor. Another wire connected to the sub-chassis screw will go out of the plinth to the preamp’s ground connection or chassis. The quality of grounding cables is not an issue, any cheap electrical cable will do. The length of the inside cable must me enough not to limit the floating sub-chassis vertical movement; the outer cable should be long enough to reach the preamplifier: