It is widespread opinion that the original rubber mats aren’t any good. Some purists of the original turntable state believe that if the mat is in good condition it shouldn’t be replaced. In the past I had replaced the original rubber mat with a very thin antistatic felt mat. Felt is appreciated for its ability to avoid the record to be electrostatically charged during the playback’s “rubbing”. But it is really thin and it can be a problem in Thorens turntables for setting the right tonearm height. The theory behind the original rubber mats was that because the metal alloy platter resonated like a bell, vibrations could be smoothed out by the rubber, which, being flexible, rests continuously and adherently on the metal platter.

Thorens TD165 with Funk Firm Achromat and graphite clamp

Later, I purchased the very good Funk Firm Achromat from England, after an enthusiastic review by Geoff Husband of TNT-Audio. At Funk Firm, they claim that the difference in composition between the vinyl of the record and the rubber of the mat causes vibrations to be reflected back into the record at the interface with the mat itself. The stuff it is made of is a kind of foamed acrylic/vinyl compound similar to PVC, therefore similar to vinyl (and there are companies that, for modest prices, could cut you a circular PVC piece with the exact dimensions for your turntable). A similar idea is used for high-end acrylic platters. It is about distributing the natural vibrations of a record in a larger volume (record + mat). Having replaced the felt mat with the Achromat I obtained a clear further sound improvement in both bass extension and general detail. Being 5 mm thick, the Achromat raised the height of the record so I had to adjust the tonearm height again, but this time from a better starting point (the felt mat was actually too thin).

I also added a 300 g graphite clamp to hold the disk tight and dampened during playback. It is usually a good idea since clamps improve the contact between record and platter (mat). One should pay attention at the clamp’s weight: Thorens turntables, like all suspended tables, require a re-adjustment of the suspension in order to reset the correct platter height following the added weight. After having purchased the Achromat I stopped using the clamp.

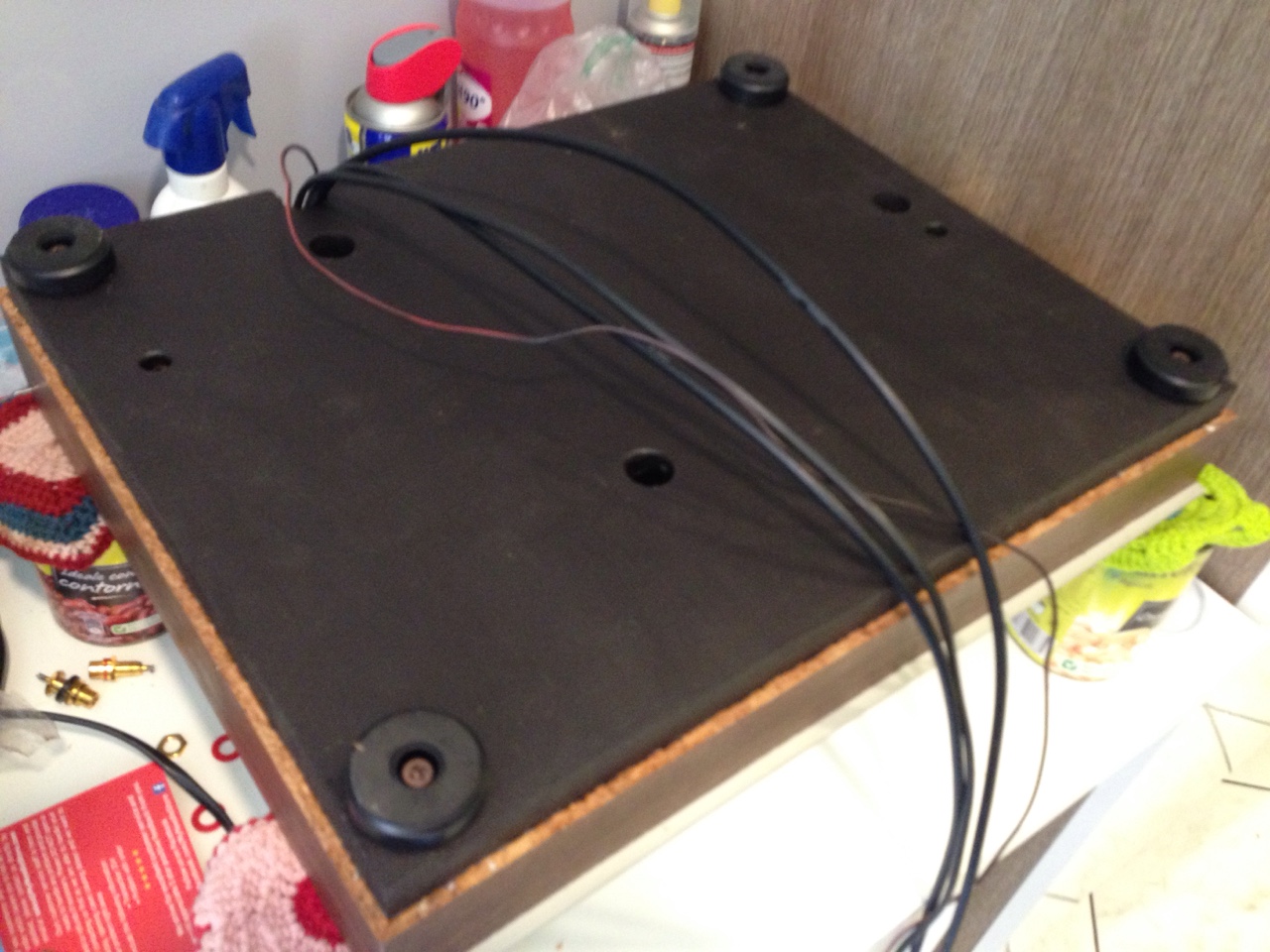

The original small rubber feet can also be replaced. Again, some purists prefer to avoid that. Some also get rid of the flimsy wooded bottom board. Some leave the plinth open, like I did for years: very comfortable for further suspension adjustments. Then I followed some others’ example and I bought a 18 mm thick MDF board. I drilled three 2-cm holes under the suspension springs and another one on the back edge to let the cables out. Then I painted the board with black acrylic paint, in the attempt to further dampen it. For the same reason, I glued some tar sheet patches in the board’s inner face. Not a back look in the end. it is similar to what Thorens itself did for their TD-160 Super. But later I went back even to using the original thin bottom board, but only after having dampened it with a good tar sheet.

For years I had replaced the original small feet with larger rubber door blocks, easily found in any hardware store (see picture at top right). Then I thought that larger plastic feet with rubber base could give the Thorens a better HiFi look. I bought a few and dampened them by filling them with the same “white tac” I’m using inside the plinth. I screwed them to the plinth at almost the same place where the original ones were.

For a while I used conical spikes under my TD160. Here again there are different currents of thought: some argue that since the conical spikes are a way of coupling, not isolating, the turntable from the support base, they can be a good addition especially if the floor of the room is suspended and vibrates when we walk. This is currently the case for me, but I must say that by properly adjusting the suspension and the cartridge’s alignment and VTF, I don’t have major footfall problems. If anything, the counter-spike discs tended to slip from their initial position at the slightest bump and perhaps I had even noticed a certain “dryness” in the sound. In the end I went back to the original rubber feet, which certainly do not slip and the sound at the moment satisfies me. It may be an idea anyway to replace them with newer, larger rubber feet.